'Mini' benchmark problem with detailed equation-based modelling

| Name | Description |

|---|---|

| OpenLoop | Open loop power system |

| OpenLoopEq | Open loop power system, modelled using equations |

| PrimaryController | Primary Control System |

| PrimaryControlledSystem | System with primary controllers connected |

| ClosedLoop | Connection of OpenLoop and Primary control systems with no secondary control. |

| ClosedLoop2 | Connection of OpenLoop and Primary with secondary control. |

| NoControl | TwoNode TestCase without primary controls |

| ShedRelay | |

| SimplePrimaryController | Primary Control System |

| SimplePrimaryControlledSystem | |

| ComparePrimaryControls | |

| OpenLoopIndexReduced | |

| VerifyIdxReduced |

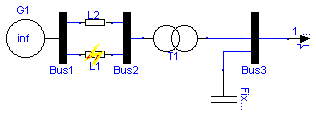

ABB_CC_Testcase.TwoNode.OpenLoop

ABB_CC_Testcase.TwoNode.OpenLoop

Model of the Open Loop mini test case built using the standard component library.

model OpenLoop "Open loop power system" Components.Slack G1(V0=1.05504739284515); Components.Bus Bus1; Components.Varimp L1; Components.Impedance L2(X=0.5); Components.Bus Bus2; Components.Bus Bus3; ABB_CC_Testcase.Components.Transformer T1(X=1e-9); input Integer LoadStep; input Integer TapStep; ABB_CC_Testcase.Components.FixCapacitor FixCapacitor1(B=0.2); Components.Load Load(P0=1, Q0=0.3); equation // L1.X = if time > 20 then Modelica.Constants.inf else 0.5; L1.X = if time > 10 then 1e5 else 0.5; Load.step = LoadStep; T1.tappos = TapStep; connect(G1.T, Bus1.T); connect(L2.T1, G1.T); connect(L1.T2, G1.T); connect(Bus2.T, T1.T1); connect(T1.T2, Bus3.T); connect(FixCapacitor1.T, Bus3.T); connect(L1.T1, Bus2.T); connect(L2.T2, Bus2.T); connect(Load.T, Bus3.T); end OpenLoop;

ABB_CC_Testcase.TwoNode.OpenLoopEq

ABB_CC_Testcase.TwoNode.OpenLoopEq

Model of the Open Loop mini test case built using direct mathematical modelling. This model is equivalent to OpenLoop.

| Name | Default | Description |

|---|---|---|

| v0 | 1.05504739284515 | |

| P0 | 1 | |

| Q0 | 0.3 | |

| B0 | 0.2 | |

| as | 0 | |

| at | 2 | |

| bs | 0 | |

| bt | 2 | |

| Tp | 60 | |

| Tq | 60 | |

| faultTime | 10 |

model OpenLoopEq "Open loop power system, modelled using equations"

// parameters

parameter Real v0=1.05504739284515;

parameter Real P0=1;

parameter Real Q0=0.3;

parameter Real B0=0.2;

parameter Real as=0;

parameter Real at=2;

parameter Real bs=0;

parameter Real bt=2;

parameter Real Tp=60;

parameter Real Tq=60;

parameter Real faultTime=10;

output Real x[2]={xp,xq};

output Real y[2](start={1,0}) = {v,delta};

input Real u[3]={n,k,X};

// variables

Real xp;

Real xq;

Real v(start=1);

Real delta;

Real k;

Real n;

Real X;

equation

// vector versions

{der(xp),der(xq)} = {(-xp/Tp + P0*(v^as - v^at)),(-xq/Tq + Q0*(v^bs - v^bt))};

{0,0} = {v*sin(delta)*v0/(X*n) + (1 - k)*(xp/Tp + P0*v^at),-(v0*v*cos(delta))

/(n*X) + v^2/(n^2*X) - B0*v^2 + (1 - k)*(xq/Tq + Q0*v^bt)};

initial equation

der(xp) = 0;

der(xq) = 0;

end OpenLoopEq;

ABB_CC_Testcase.TwoNode.PrimaryController

ABB_CC_Testcase.TwoNode.PrimaryController

This model models the primary control systems of the four node power system. It contains a tap changer controller for transformer T1 modelled as a state machine and an automatic voltage regulator with filed voltage limiter modelled by a state machina and a linear control law. The special equations activated by the flag SimulinkSafe flag are jus fixes that must be applied to make the model simulable with Simulink. If you remodel this system with other tools, use the original equations (assume that SimulinkSafe=false)

| Name | Default | Description |

|---|---|---|

| idle0 | false | |

| wait0 | true | |

| action0 | false | |

| tappos0 | 0 | |

| timer0 | 0 | |

| up_limit0 | false | |

| TapDelay | 30 | |

| MechDelay | 1 | |

| TapDB | 0.01*3 | |

| MaxTap | 10 | |

| MinTap | -10 |

model PrimaryController "Primary Control System"

parameter Boolean idle0=false;

parameter Boolean wait0=true;

parameter Boolean action0=false;

parameter Integer tappos0=0;

parameter Real timer0=0;

parameter Boolean up_limit0=false;

input Real TapVref(start=1);

input Real v(start=1);

Boolean idle(start=idle0, fixed=true);

Boolean wait(start=wait0, fixed=true);

Boolean action(start=action0, fixed=true);

Integer tappos(start=tappos0, fixed=true);

Real timer(start=timer0, fixed=true);

Boolean toohigh;

Boolean toolow;

output Integer T1tappos;

parameter Real TapDelay=30;

parameter Real MechDelay=1;

parameter Real TapDB=0.01*3;

parameter Real MaxTap=10;

parameter Real MinTap=-10;

equation

T1tappos = pre(tappos);

// tap changer control - state automata !

toohigh = (v - TapVref) > TapDB/2;

toolow = (v - TapVref) < -TapDB/2;

idle = (pre(idle) or pre(wait)) and not (toohigh or toolow) or (pre(action)

and ((time - timer) > TapDelay + MechDelay));

wait = (pre(idle) and (toohigh or toolow)) or pre(wait) and ((toolow or

toohigh) and ((time - pre(timer)) < TapDelay));

action = (pre(wait) and (time - timer > TapDelay)) or pre(action) and ((time

- timer) < TapDelay + MechDelay);

when wait and not pre(wait) and not initial() then

timer = time;

end when;

when pre(action) and not action then

if toolow and (pre(tappos) < MaxTap) then

tappos = pre(tappos) + 1;

elseif toohigh and (pre(T1tappos) > MinTap) then

tappos = pre(tappos) - 1;

else

tappos = pre(tappos);

end if;

end when;

end PrimaryController;

Connection of OpenLoop and Primary control systems

| Name | Default | Description |

|---|---|---|

| faultTime | 10 | |

| tapstepsize | 0.02 | |

| loadstepsize | 0.05 |

model PrimaryControlledSystem

"System with primary controllers connected"

ABB_CC_Testcase.TwoNode.OpenLoopEq System;

ABB_CC_Testcase.TwoNode.PrimaryController PrimCon;

parameter Real faultTime=10;

parameter Real tapstepsize=0.02;

parameter Real loadstepsize=0.05;

input Real LoadStep;

equation

System.u = {1 + tapstepsize*PrimCon.T1tappos,LoadStep*loadstepsize,if time >

faultTime then 0.5 else 0.25};

PrimCon.v = System.v;

PrimCon.TapVref = 1;

end PrimaryControlledSystem;

Connection of OpenLoop and Primary control systems with no secondary control.

model ClosedLoop "Connection of OpenLoop and Primary control systems with no secondary control." ABB_CC_Testcase.TwoNode.PrimaryControlledSystem System(faultTime=90); equation System.LoadStep = 0; end ClosedLoop;

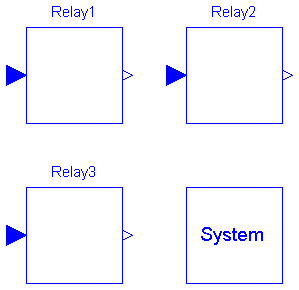

Connection of OpenLoop and Primary control systems with secondary control using undervoltage load shedding relays.

model ClosedLoop2

"Connection of OpenLoop and Primary with secondary control."

ShedRelay Relay1(

Threshold=.8,

DelayTime=1.5,

ShedAmount=.05);

ShedRelay Relay2(

Threshold=.82,

DelayTime=3,

ShedAmount=.05);

ShedRelay Relay3(

DelayTime=6,

ShedAmount=0.05,

Threshold=.92);

equation

Relay1.inPort.signal[1] = System.System.v;

Relay2.inPort.signal[1] = System.System.v;

Relay3.inPort.signal[1] = System.System.v;

System.System.k = Relay1.y + Relay2.y + Relay3.y;

public

ABB_CC_Testcase.TwoNode.PrimaryControlledSystem System;

end ClosedLoop2;

This is a model of the twonode testcase, where no primary control systems has been connected. Instead the tap ratio is fixed at 1 p.u. and the load shedding input at 0 p.u. A fault on the the line is modelled of the change of the line impedance from 0.25 to 0.5 p.u. at time 10 s.

| Name | Default | Description |

|---|---|---|

| faultTime | 30 |

model NoControl "TwoNode TestCase without primary controls"

parameter Real faultTime=30;

ABB_CC_Testcase.TwoNode.OpenLoopEq System;

equation

System.u = {1,0,if time > faultTime then 0.5 else 0.25};

end NoControl;

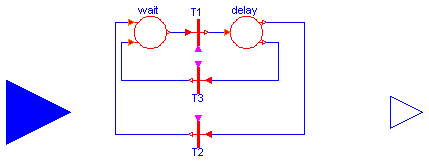

ABB_CC_Testcase.TwoNode.ShedRelay

ABB_CC_Testcase.TwoNode.ShedRelay

Standard load shedding relay.

| Name | Default | Description |

|---|---|---|

| Threshold | 0.95 | |

| DelayTime | 1 | |

| ShedAmount | 0.05 |

class ShedRelay

extends Modelica.Blocks.Interfaces.SISO;

parameter Real Threshold=0.95;

parameter Real DelayTime=1;

parameter Real ShedAmount=0.05;

discrete Real timerstart(start=-1, fixed=true);

ModelicaAdditions.PetriNets.Transition T1;

ModelicaAdditions.PetriNets.Transition T2;

ModelicaAdditions.PetriNets.Place12 delay;

ModelicaAdditions.PetriNets.Transition T3;

ModelicaAdditions.PetriNets.Place21 wait(initialState=true);

equation

connect(delay.inTransition, T1.outTransition);

connect(T3.inTransition, delay.outTransition1);

connect(delay.outTransition2, T2.inTransition);

connect(T1.inTransition, wait.outTransition);

connect(T2.outTransition, wait.inTransition2);

connect(T3.outTransition, wait.inTransition1);

T1.condition = (u < Threshold) and (y < ShedAmount/10);

T2.condition = (u > Threshold);

T3.condition = time > timerstart + DelayTime;

when delay.state then

timerstart = time;

end when;

when T3.condition and delay.state then

outPort.signal[1] = ShedAmount;

end when;

initial equation

wait.state = true;

delay.state = false;

y = 0;

end ShedRelay;

ABB_CC_Testcase.TwoNode.SimplePrimaryController

ABB_CC_Testcase.TwoNode.SimplePrimaryController

This model models the primary control systems of the four node power system using a simplified discrete-time approximation.

| Name | Default | Description |

|---|---|---|

| tappos0 | 0 | |

| up_limit0 | false | |

| TapDelay | 30 | |

| MechDelay | 1 | |

| TapDB | 0.01*3 | |

| MaxTap | 10 | |

| MinTap | -10 |

model SimplePrimaryController "Primary Control System"

parameter Integer tappos0=0;

parameter Boolean up_limit0=false;

input Real TapVref(start=1);

input Real v(start=1);

Integer tappos(start=tappos0, fixed=true);

Boolean toohigh;

Boolean toolow;

output Integer T1tappos;

parameter Real TapDelay=30;

parameter Real MechDelay=1;

parameter Real TapDB=0.01*3;

parameter Real MaxTap=10;

parameter Real MinTap=-10;

equation

when sample(0, TapDelay + MechDelay) then

// tap changer control - simple discrete implementation

toohigh = (v - TapVref) > TapDB/2;

toolow = (v - TapVref) < -TapDB/2;

if toolow and (pre(tappos) < MaxTap) then

tappos = pre(tappos) + 1;

elseif toohigh and (pre(T1tappos) > MinTap) then

tappos = pre(tappos) - 1;

else

tappos = pre(tappos);

end if;

end when;

T1tappos = pre(tappos);

end SimplePrimaryController;

| Name | Default | Description |

|---|---|---|

| faultTime | 10 | |

| tapstepsize | 0.02 | |

| loadstepsize | 0.05 |

model SimplePrimaryControlledSystem

ABB_CC_Testcase.TwoNode.OpenLoopEq System;

ABB_CC_Testcase.TwoNode.SimplePrimaryController PrimCon;

parameter Real faultTime=10;

parameter Real tapstepsize=0.02;

parameter Real loadstepsize=0.05;

input Real LoadStep;

equation

System.u = {1 + tapstepsize*PrimCon.T1tappos,LoadStep*loadstepsize,if time >

faultTime then 0.5 else 0.25};

PrimCon.v = System.v;

PrimCon.TapVref = 1;

end SimplePrimaryControlledSystem;

model ComparePrimaryControls ABB_CC_Testcase.TwoNode.SimplePrimaryControlledSystem SimpleSystem; ABB_CC_Testcase.TwoNode.PrimaryControlledSystem System; equation System.LoadStep = 0; SimpleSystem.LoadStep = 0; end ComparePrimaryControls;

ABB_CC_Testcase.TwoNode.OpenLoopIndexReduced

ABB_CC_Testcase.TwoNode.OpenLoopIndexReducedModel of the Open Loop mini test case built using direct mathematical modelling. This model is equivalent to OpenLoop.

| Name | Default | Description |

|---|---|---|

| v0 | 1.05504739284515 | |

| P0 | 1 | |

| Q0 | 0.3 | |

| B0 | 0.2 | |

| as | 0 | |

| at | 2 | |

| bs | 0 | |

| bt | 2 | |

| Tp | 60 | |

| Tq | 60 | |

| faultTime | 10 |

model OpenLoopIndexReduced

// parameters

parameter Real v0=1.05504739284515;

parameter Real P0=1;

parameter Real Q0=0.3;

parameter Real B0=0.2;

parameter Real as=0;

parameter Real at=2;

parameter Real bs=0;

parameter Real bt=2;

parameter Real Tp=60;

parameter Real Tq=60;

parameter Real faultTime=10;

output Real x[2]={xp,xq};

output Real y[2](start={1,0}) = {v,delta};

input Real u[3]={n,k,X};

Real[2, 2] gx;

Real[2, 2] gy;

Real[2, 1] f;

Real[2, 1] g;

Real[2, 2] invgy;

// variables

Real xp;

Real xq;

Real v(start=1);

Real delta;

Real k;

Real n;

Real X;

equation

// vector versions

f = [-xp/Tp + P0*(v^as - v^at); -xq/Tq + Q0*(v^bs - v^bt)];

[der(xp); der(xq)] = f;

g = [v*sin(delta)*v0/(X*n) + (1 - k)*(xp/Tp + P0*v^at); -(v0*v*cos(delta))/(n

*X) + v^2/(n^2*X) - B0*v^2 + (1 - k)*(xq/Tq + Q0*v^bt)];

gx = [(1 - k)/Tp, 0; 0, (1 - k)/Tq];

gy = [sin(delta)*v0/X/n + (1 - k)*P0*v^at*at/v, v0*v*cos(delta)/X/n; -v0*cos(

delta)/X/n + 2*v/n^2/X - 2*B0*v + (1 - k)*Q0*v^bt*bt/v, v*sin(delta)*v0/X/n];

invgy = [v*sin(delta)*X*n^2/(sin(delta)^2*n*v0*v - sin(delta)*n^2*P0*v^at*at*

X*k + sin(delta)*n^2*P0*v^at*at*X + v0*cos(delta)^2*n*v - 2*cos(delta)*v^2

+ 2*cos(delta)*B0*v^2*X*n^2 + cos(delta)*Q0*v^bt*bt*X*n^2*k - cos(delta)*

Q0*v^bt*bt*X*n^2), -v*cos(delta)*X*n^2/(sin(delta)^2*n*v0*v - sin(delta)*n^

2*P0*v^at*at*X*k + sin(delta)*n^2*P0*v^at*at*X + v0*cos(delta)^2*n*v - 2*

cos(delta)*v^2 + 2*cos(delta)*B0*v^2*X*n^2 + cos(delta)*Q0*v^bt*bt*X*n^2*k

- cos(delta)*Q0*v^bt*bt*X*n^2); (v0*cos(delta)*n*v - 2*v^2 + 2*B0*v^2*X*n^

2 + Q0*v^bt*bt*X*n^2*k - Q0*v^bt*bt*X*n^2)*X*n/v/v0/(sin(delta)^2*n*v0*v -

sin(delta)*n^2*P0*v^at*at*X*k + sin(delta)*n^2*P0*v^at*at*X + v0*cos(delta)

^2*n*v - 2*cos(delta)*v^2 + 2*cos(delta)*B0*v^2*X*n^2 + cos(delta)*Q0*v^bt*

bt*X*n^2*k - cos(delta)*Q0*v^bt*bt*X*n^2), -(-sin(delta)*v0*v + P0*v^at*at*

X*n*k - P0*v^at*at*X*n)*X*n^2/v/v0/(sin(delta)^2*n*v0*v - sin(delta)*n^2*P0

*v^at*at*X*k + sin(delta)*n^2*P0*v^at*at*X + v0*cos(delta)^2*n*v - 2*cos(

delta)*v^2 + 2*cos(delta)*B0*v^2*X*n^2 + cos(delta)*Q0*v^bt*bt*X*n^2*k -

cos(delta)*Q0*v^bt*bt*X*n^2)];

// [0; 0] = g;

// [der(v); der(delta)] = -invgy*gx*f;

[0; 0] = gx*f + gy*[der(v); der(delta)];

initial equation

gx*f = [0; 0];

g = [0; 0];

end OpenLoopIndexReduced;

model VerifyIdxReduced

OpenLoopIndexReduced OpenLoopIndexReduced1;

equation

OpenLoopIndexReduced1.u = {1,0,if time > 10 then 0.5 else 0.25};

end VerifyIdxReduced;