Small scale benchmark system

| Name | Description |

|---|---|

| OpenLoop | Open loop power system |

| PrimaryController | Primary Control System |

| PrimaryControlledSystem | Test case power system with example primary controls applied |

| ClosedLoop | Test case power system with example emergency control applied |

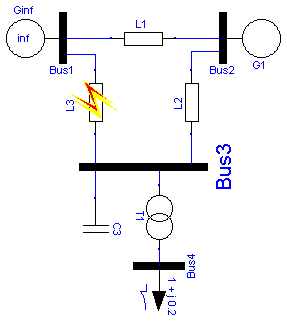

ABB_CC_Testcase.Fournode.OpenLoop

ABB_CC_Testcase.Fournode.OpenLoop

Test case power system without primary controls is a nonlinear

system with pure continuous dynamics.

The open loop power system has four control inputs:

CapStep

Nr of capacitor steps connected at bus 3

can assume the values [0,1,2,3]. Each step corresponds

to 0.1 p.u. of compensation.

LoadStep

The nr of load shedding steps used at bus 4

can assume the values [0,1,2,3]. Each step corresponds

TrStep

The position of the tap changer on transformer T1

G1Efd

The field voltage of generator G1

The test case has one disturbance input:

faulted

Boolean variable indicating whether or not line L3 is faulted.

The fault is modelled by the change of the impedance of the line

from 1 p.u. to 1.5 p.u.

The open loop power system has three controlled outputs:

V2,V3,V4

The voltage at buses 2,3 and 4 respectively.

The aim of emergency control is to keep the voltages

V2,V3,V4 within the limits [0.9 p.u. and 1.1 p.u.] despite

the fault input becoming true.

Additionally the two dynamic states has bee included as auxilliary outputs:

xp,xq

The two dynamic state variables

Recommended initial input values are:

CapStep=2, LoadStep=0, TrStep=1, and faulted=false (0)

| Name | Default | Description |

|---|---|---|

| L3X_1 | 0.5 | |

| L3X_2 | 1.5 | |

| SimulinkSafe | true | |

| G1 | redeclare Components.GenQSS2 G1(xd=2.38, xq=2.27, xdp=0.91, Td0p=9.6) |

model OpenLoop "Open loop power system"

parameter Real L3X_1=0.5;

parameter Real L3X_2=1.5;

input Integer CapStep;

input Integer LoadStep;

input Integer TrStep(start=1);

input Real G1Efd;

input Boolean faulted;

output Real V2;

output Real V3;

output Real V4;

output Real xp;

output Real xq;

parameter Boolean SimulinkSafe=true;

protected

constant Real Ef0=1.55;

public

Components.Transformer T1(X=0.0031);

Components.Capacitor C3;

Components.Varimp L3;

Components.Bus Bus1;

Components.Bus Bus2;

Components.Bus Bus3;

Components.Bus Bus4;

Components.Slack Ginf(V0=1.03);

Components.Impedance L1(X=0.75);

Components.Impedance L2(X=0.7);

Components.Load Load(

P0=1,

Q0=0.2,

as=0,

at=2,

bs=1,

bt=2);

replaceable Components.GenQSS2 G1(

xd=2.38,

xq=2.27,

xdp=0.91,

Td0p=9.6);

equation

connect(Bus4.T, T1.T2);

connect(C3.T, Bus3.T);

connect(T1.T1, Bus3.T);

connect(L3.T1, Bus3.T);

connect(L2.T1, Bus3.T);

connect(Bus1.T, Ginf.T);

connect(L1.T2, Bus2.T);

connect(Bus2.T, L2.T2);

connect(L3.T2, Ginf.T);

connect(Ginf.T, L1.T1);

connect(Load.T, Bus4.T);

connect(Bus2.T, G1.T);

if SimulinkSafe then

G1.Efd = if noEvent(abs(G1Efd) > 1e-5) then G1Efd else Ef0;

else

G1.Efd = G1Efd;

end if;

C3.step = CapStep;

Load.step = LoadStep;

T1.tappos = TrStep;

V2 = Bus2.V;

V3 = Bus3.V;

V4 = Bus4.V;

xp = Load.xp;

xq = Load.xp;

L3.X = if faulted then L3X_2 else L3X_1;

end OpenLoop;

ABB_CC_Testcase.Fournode.PrimaryController

ABB_CC_Testcase.Fournode.PrimaryController

This model models the primary control systems of the four node power system. It contains a tap changer controller for transformer T1 modelled as a state machine and an automatic voltage regulator with filed voltage limiter modelled by a state machina and a linear control law. The special equations activated by the flag SimulinkSafe flag are just fixes that must be applied to make the model simulable with Simulink. If you remodel this system with other tools, use the original equations (assume that SimulinkSafe=false)

| Name | Default | Description |

|---|---|---|

| idle0 | false | |

| wait0 | true | |

| action0 | false | |

| tappos0 | 1 | |

| timer0 | 0 | |

| up_limit0 | false | |

| G1Vref | 1.03 | |

| Ef0 | 1.55 | |

| Efmax | 2.2 | |

| TapDelay | 30 | |

| MechDelay | 1 | |

| TapDB | 0.01*3 | |

| MaxTap | 10 | |

| MinTap | -10 | |

| SimulinkSafe | true |

model PrimaryController "Primary Control System"

parameter Boolean idle0=false;

parameter Boolean wait0=true;

parameter Boolean action0=false;

parameter Integer tappos0=1;

parameter Real timer0=0;

parameter Boolean up_limit0=false;

input Real TapVref(start=1);

input Real V2(start=1);

input Real V3(start=1);

input Real V4(start=1);

Boolean idle(start=idle0, fixed=true);

Boolean wait(start=wait0, fixed=true);

Boolean action(start=action0, fixed=true);

Integer tappos(start=tappos0, fixed=true);

Real timer(start=timer0, fixed=true);

Boolean up_limit(start=up_limit0, fixed=true);

Boolean toohigh;

Boolean toolow;

output Real G1Efd;

output Integer T1tappos;

parameter Real G1Vref=1.03;

parameter Real Ef0(

min=1.5,

max=9) = 1.55;

parameter Real Efmax=2.2;

parameter Real TapDelay=30;

parameter Real MechDelay=1;

parameter Real TapDB=0.01*3;

parameter Real MaxTap=10;

parameter Real MinTap=-10;

Real Efd(start=1.55);

parameter Boolean SimulinkSafe=true;

equation

// generator voltage control

if SimulinkSafe then

0.01*der(Efd) + Efd = if up_limit then Efmax else Ef0 + (G1Vref - V2)*50;

else

Efd = if up_limit then Efmax else Ef0 + (G1Vref - V2)*50;

end if;

T1tappos = pre(tappos);

G1Efd = Efd;

// tap changer control - state automata !

toohigh = (V4 - TapVref) > TapDB/2;

toolow = (V4 - TapVref) < -TapDB/2;

idle = (pre(idle) or pre(wait)) and not (toohigh or toolow) or (pre(action)

and ((time - timer) > TapDelay + MechDelay));

wait = (pre(idle) and (toohigh or toolow)) or pre(wait) and ((toolow or

toohigh) and ((time - pre(timer)) < TapDelay));

action = (pre(wait) and (time - timer > TapDelay)) or pre(action) and ((time

- timer) < TapDelay + MechDelay);

up_limit = if not (pre(up_limit)) then (Efd > Efmax) else not (V2 > G1Vref);

when wait and not pre(wait) and not initial() then

timer = time;

end when;

when pre(action) and not action then

if toolow and (pre(tappos) < MaxTap) then

tappos = pre(tappos) + 1;

elseif toohigh and (pre(T1tappos) > MinTap) then

tappos = pre(tappos) - 1;

else

tappos = pre(tappos);

end if;

end when;

end PrimaryController;

| Name | Default | Description |

|---|---|---|

| SimulinkSafe | false |

model PrimaryControlledSystem "Test case power system with example primary controls applied" input Integer CapStep; input Integer LoadStep; input Real TapVref; input Boolean faulted; output Real V2; output Real V3; output Real V4; output Real G1Efd; parameter Boolean SimulinkSafe=false; // auxilliary outputs output Real U1d; output Real U1q; output Real U2d; output Real U2q; output Real U3d; output Real U3q; output Real U4d; output Real U4q; output Real I1d; output Real I1q; output Real I2d; output Real I2q; output Real I3d; output Real I3q; output Real I4d; output Real I4q; output Real I5d; output Real I5q; output Real Icd; output Real Icq; output Real U2m; output Real U4m; output Real U4m2; output Real Efd; output Real P5l; output Real Q5l; output Integer T1_tappos; output Real T1_timer; output Real Load_xp; output Real Load_xq; output Boolean T1_idle; output Boolean T1_wait; output Boolean T1_action; output Boolean G1_up_limit; OpenLoop System(SimulinkSafe=SimulinkSafe); PrimaryController Controller(Ef0=1.54, SimulinkSafe=SimulinkSafe); equation V2 = System.V2; V3 = System.V3; V4 = System.V4; G1Efd = Controller.G1Efd; Controller.TapVref = TapVref; System.LoadStep = LoadStep; System.CapStep = CapStep; Controller.V2 = System.V2; Controller.V3 = System.V3; Controller.V4 = System.V4; System.G1Efd = Controller.G1Efd; System.TrStep = Controller.T1tappos; System.faulted = faulted; U1d = System.Bus1.T.va; U1q = System.Bus1.T.vb; U2d = System.Bus2.T.va; U2q = System.Bus2.T.vb; U3d = System.Bus3.T.va; U3q = System.Bus3.T.vb; U4d = System.Bus4.T.va; U4q = System.Bus4.T.vb; I1d = System.Ginf.T.ia; I1q = System.Ginf.T.ib; I2d = System.G1.T.ia; I2q = System.G1.T.ib; I3d = System.T1.T1.ia; I3q = System.T1.T1.ib; I4d = System.T1.T2.ia; I4q = System.T1.T2.ib; I5d = System.Load.T.ia; I5q = System.Load.T.ib; Icd = System.C3.T.ia; Icq = System.C3.T.ib; U2m = System.Bus2.V; U4m = System.Bus4.V; U4m2 = System.Bus4.V^2; Efd = System.G1.Efd; P5l = System.Load.Pl; Q5l = System.Load.Ql; T1_tappos = Controller.tappos; T1_timer = Controller.timer; Load_xp = System.Load.xp; Load_xq = System.Load.xq; T1_idle = Controller.idle; T1_wait = Controller.wait; T1_action = Controller.action; G1_up_limit = Controller.up_limit; end PrimaryControlledSystem;

This model illustrates three possibilities of emergency control. The aim of the emergeny control is to stabilize the voltage of Bus 4 at a value higher than 0.9 p.u. It is trivial to design emergency control strategies that will arrest the voltage collapse for a simple with this simple structure based on heuristics. strategy=0: No emergency control, the voltage collapses after 568.5. strategy=1: Attempt to stabilize by change of transformer voltage control setpoint, strategy=2: Stabilitation by capacitor switching strategy=3: Stabilization by capacitor swithcing and tap reference change strategy=4: Stabilization by load shedding

| Name | Default | Description |

|---|---|---|

| strategy | 3 | |

| FaultTime | 100 | |

| TimeOfControl | 110 |

model ClosedLoop

"Test case power system with example emergency control applied"

parameter Integer strategy=3;

parameter Real FaultTime=100;

parameter Real TimeOfControl=110;

output Real V2;

output Real V3;

output Real V4;

output Real Efd;

ABB_CC_Testcase.Fournode.PrimaryControlledSystem PCS;

equation

// control strategy

if strategy == 0 then

// no emergency control

PCS.TapVref = 1;

PCS.CapStep = 2;

PCS.LoadStep = 0;

elseif strategy == 1 then

//attempt to stabilize by tap reference change

PCS.TapVref = if time > TimeOfControl then 0.92 else 1;

PCS.CapStep = 2;

PCS.LoadStep = 0;

elseif strategy == 2 then

//attempt to stabilize by cap switching

PCS.TapVref = 1;

PCS.CapStep = if time > TimeOfControl then 3 else 2;

PCS.LoadStep = 0;

elseif strategy == 3 then

//succesful stabilization by cap switching and tap reference change

PCS.TapVref = if time > TimeOfControl then 0.92 else 1;

PCS.CapStep = if time > TimeOfControl then 3 else 2;

PCS.LoadStep = 0;

elseif strategy == 4 then

// stabilization by load shedding

PCS.TapVref = 1;

PCS.CapStep = 2;

PCS.LoadStep = if time > TimeOfControl then 3 else 0;

end if;

PCS.faulted = if time > FaultTime then true else false;

V2 = PCS.System.V2;

V3 = PCS.System.V3;

V4 = PCS.System.V4;

Efd = PCS.Controller.Efd;

end ClosedLoop;